Background and circular economy

WE-EF is a global lighting manufacturer that was founded in 1950 in Germany and started its operation in Australia in 1994. WE-EF high-quality outdoor luminaires are independent in design with an innovation and sustainability focus.

WE-EF seeks optimal use for their lighting products designed and manufactured with a prolonged lifespan in mind to place themselves on the circular economy value hill. It demonstrates a progressing level of maturity (14/25) in circular economy adoption. They are familiar with the rules of circular economy, and aware of the environmental impact. They also monitor environmental indicators, have an environmental management system and have pragmatic and altruistic reasons for limiting environmental impacts.

Drivers for circular economy adoption

The drive for circular economy adoption was based on the values of the management team (and employees) and the parent company's push to make the company circular.

Circular economy practices adopted

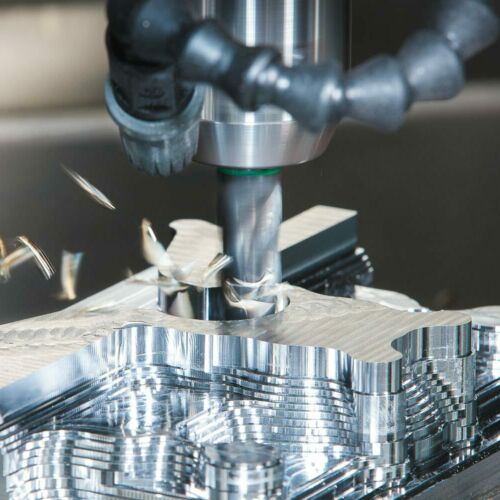

- Design out waste in manufacturing

- Reduce energy use via efficient lighting on premises (e.g., adopting control solutions that enable lights to be off or dimmed until motion is detected)

- Solar panels for renewable energy generation

- Use of high-quality material in manufacturing (>90%recycled, refined authentic aluminium)

- Prolonged lifespan for products by design

- Embedding the International Dark Sky Association principles for Responsible Outdoor Lighting in strategies and practices

- Energy efficiency for products by design (from concept stage the product lifecycle is considered)

Company changes with the adoption of circular economy

They initiated their journey into the circular economy in 2022, with the backing of the parent company that has nominated their Australian operation to be the pilot project for their global operation.

Barriers and challenges

Barriers and challenges include:

- Higher product costs due to better material use

- Keeping updated with new practices

- Lack of recycle options

- Customers’ awareness of benefits of paying a premium for an environmentally friendly and durable product

- Limited integration of overseas supply chain

Critical success factors for circular economy

Critical success factors include:

- Leadership's vision, both locally and from the parent company

- Openness to learning and willingness to educate the workforce

- Digitalisation of internal processes

- Collaboration and knowledge sharing with distributors and customers

Benefits of adopting a circular economy

They feel that introducing circular economy practices may result in creating a better culture within the company, while externally providing branding benefits.