Background and circular economy

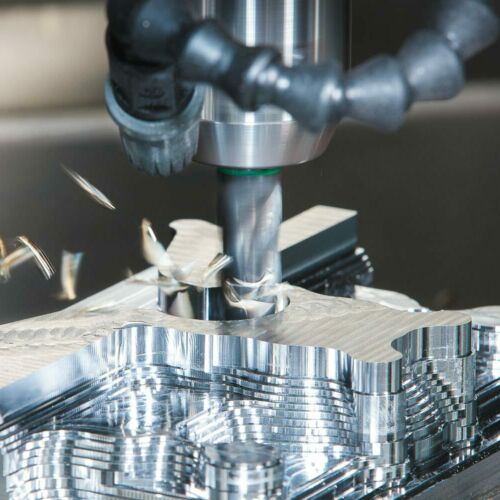

Arrow started specialising in mechanical components in 2016, supplying parts and services to industrial niches. They also design and build precision machines to perform a wide range of functions.

Their products are designed to last longer and provide the customers with optimal repair services, which place their business high on the circular economy value hill.

Arrow demonstrates an advancing level of maturity (15/25), with their familiarity with the rules of the circular economy. Some of these are their environmental impact awareness, having most of the processes for environmental activities identified and defined while demonstrating pragmatic and altruistic reasons for limiting environmental impacts.

Drivers for circular economy adoption

Personal values and a passion for sustainability were the driving force behind their adoption of the circular economy business model. Seeing the business potential has driven them towards circularity, complemented by government support (including grants), have encouraged them.

Circular economy practices adopted

- Designs to reduce waste

- Efficient machinery use

- Reduce and reuse plastic wrapping

- Installing solar panels

- Energy efficiency

- Use long-lasting, better-quality material

- Repair service for customers

Company changes with the adoption of circular economy

They have been progressively seeking better quality material and efficient machines that reduce the waste of raw material. Regenerative energy generated by solar panels power the factory building but are not sophisticated enough to power the machinery.

Barriers and challenges

Barriers and challenges include:

- Competing priorities of survival and environmental practices

- Higher product costs due to the additional improvement of circular economy practices

- Financial constraints of an SME business

- Being aware of and keeping updated with new practices

- Lack of manufacturing in Australia

- Insufficient environmentally accredited supplies

- Customers’ reluctance for circularity

- Having no centralised platform to share resources

- Lack of policy regulation to drive others' circular economy practices, including outdated legislation, and inconsistent rules and regulations from different government bodies/departments

Critical success factors for circular economy

Critical success factors include:

- The vision and commitment of the leadership and their willingness to educate the workforce

- Openness to learn while persisting in the circular journey as a long-term strategy

- Collaborating with external parties to gain new circular economy knowledge and skills

- Working together with suppliers to extend their circular practices

Benefits of adopting a circular economy

Arrow MPS's determination to adopt a circular economy as a long-term strategy has so far created a better culture and feel-good environment within the company, while being able to provide better products and services to the customer. They believe that growing maturity in circularity will reap further rewards.