Background and circular economy

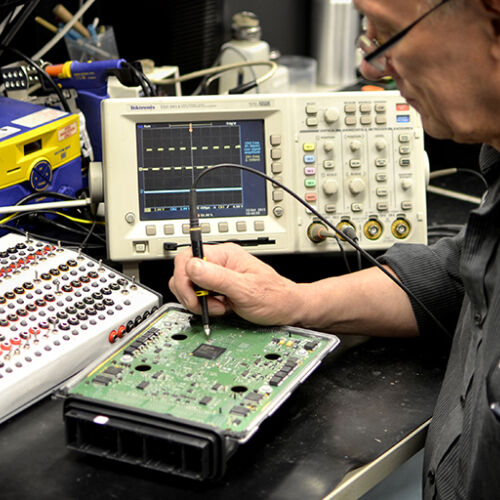

Operating since 1983, IM Group are leaders in electronic and mechatronic components, and sustainable power storage solutions. They have provided products and services of the highest quality (i.e., remanufactures automotive mechatronics components). It is essentially an upcycling business, where they take a non-functioning, automotive electronic component, strip it down and remanufacture it.

IM Group promotes value retention of automotive electronic components to place themselves on the circular economy value hill. They demonstrate a championing level of maturity in the circular economy (25/25). They do this through process monitoring and improvements in circular economy practices, raising stakeholders' awareness of environmental impacts, and following a formalized environmental management system.

Drivers for circular economy adoption

Their key drivers towards circularity are seeing the business potential and financial benefits, seeing the opportunity to produce quality products by incorporating waste, and wanting to transform the company to lead the industry for sustainability. The opportunity to gain a competitive edge in the market and government grants have driven them further towards circular economy practices.

Circular economy practices adopted

- Take back only used or non-functioning automotive electronic components

- Reduce waste in manufacturing

- Reduce waste of inputs

- Resell used electronic components after service

- Repair non-functioning electronic components

- Refurbish non-functioning electronic components by replacing non-functioning parts

- Repurpose non-functioning parts to build functioning electronic components

- Components that are not fit for the same purpose used for a different purpose

Company changes with the adoption of circular economy

IM Group started with parts and components supply, and testing and validating in the automotive mechatronic industry. They then transformed themselves towards the repair and remanufacturing, while further strengthening their research and development to facilitate circular economy model adoption.

Barriers and challenges

Barriers and challenges include:

- Shortage of specialised human resources

- Securing waste streams (electronic components) as inputs

- Material which are not fit for upcycling/recycling

- Lack of customer awareness of environmental options of products

- Lack of policy and regulation to drive the circular economy model

Critical success factors for circular economy

Critical success factors include:

- Vision and commitment of the leadership

- Developing a viable business model with circularity built-in at all stages

- Digitalisation of business processes

- Collaboration with external stakeholders

Benefits of adopting a circular economy

IM Group has managed to reap economic benefits by implementing a circular economy model, and helped them develop and retain a customer base and provide a good quality product.